Radiators filled. System pressurised. And action!

It was almost destined not to happen, but after months of pain, disruption, and switching companies, the air source heat pump (ASHP for those in the know, or if you want to be pretentious) installation is finally happening. Octopus Energy is the force behind it, and they have been moving with lightning speed to get it done.

The team are all incredibly friendly and happy to make adjustments (within reason) according to our preferences about routes of piping and positioning of equipment. How British Gas planned to fit all the required equipment for the hot water cylinder into the cupboard of the existing cylinder was beyond me. They decided that was the best route rather than have a short run from the heat pump and into effectively a plant room, which is what Octopus Energy have opted for.

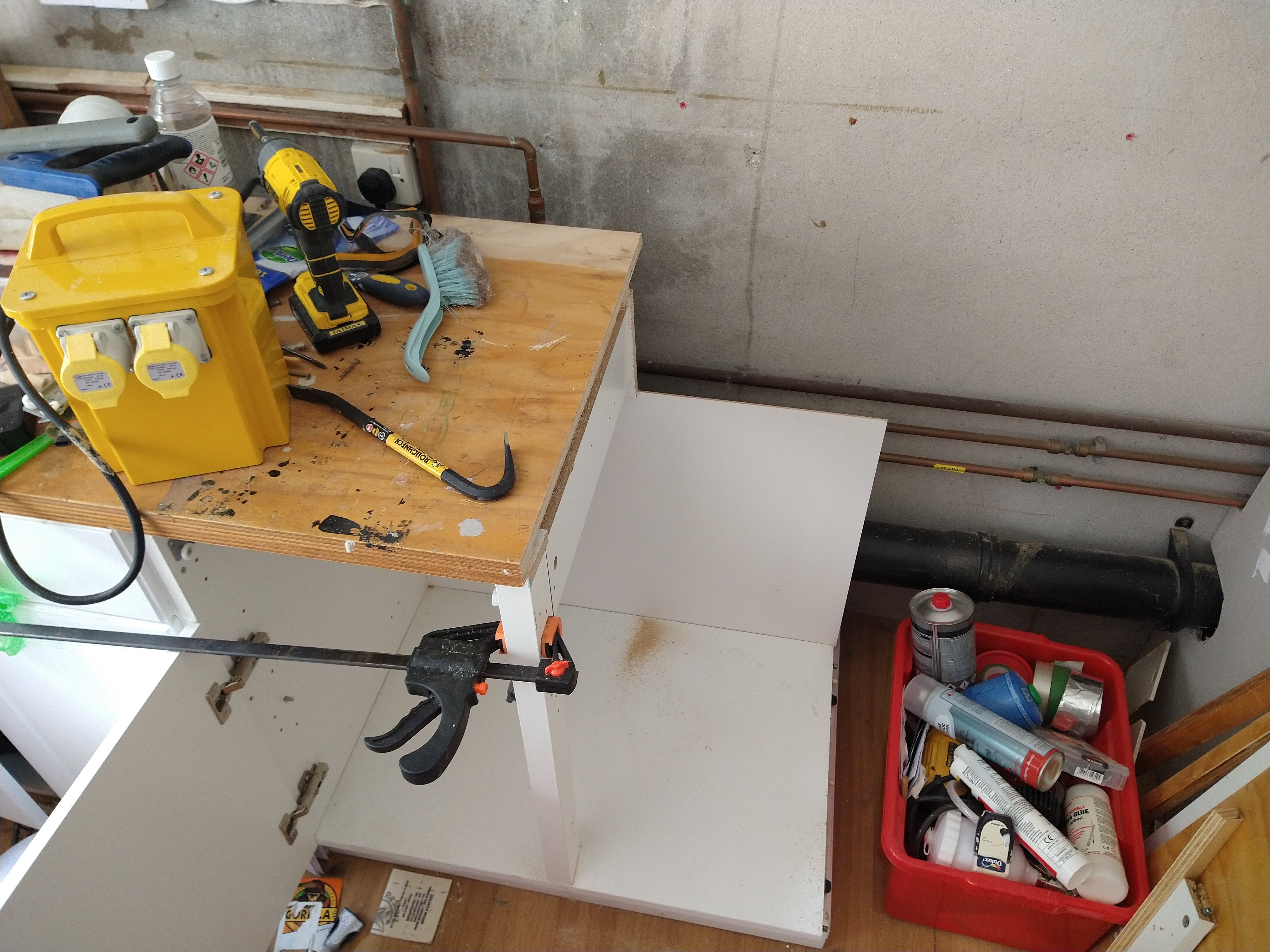

Losing space in the workshop is less than ideal, but it’s something I’m willing to compromise on. I cut off half of a cupboard at the end of the worktop and boxed it in to create a larger space for the kit. I’m on the fence about getting rid of the sink. It’s useful occasionally although I would like a bit more usable workspace.

The Plan

Rather than stripping out and re-piping everything like lunatics, Octopus were only going to replace radiators as necessary, and add several to rooms that were previously unconnected to the central heating. There has still been a lot of work given the difficulty getting pipe to some of the areas. The previous owners of our house decided wisely to remove radiators and pipework from a number of rooms leaving us with no choice other than to get creative. The radiators were removed from the conservatory and the plastic piping was used to feed the new piping.

The new run to the back bedroom and kitchen goes across the conservatory wall and under the floor upstairs. There are some pipes on display but that was always going to be the case with retrofitting, and on the whole the work is very neat.

The main bathroom has lost a towel rail in favour of a small double panel radiator, and the ensuite is getting a tall towel rail, albeit in a different position. Most of the radiators upstairs are unchanged as they were adequate rated for the calculated levels of heat loss.

Spaghetti Junction

The previous installation had pipes and wires running all over the wall in a maddening configuration. One of the nice things about a new system is that a lot of those pipes have been stripped out and replaced with ones on a straighter run positioned logically. The same with the electrical work, although I have lost a socket in the process which is slightly less convenient. It was an old and slightly dodgy one, but a socket nonetheless.

What’s left to do?

The system is all piped in and the heat pump is in place, all ready for commissioning tomorrow. There are a few bits to be tidied up here and there and I need to do some painting as some of the radiators are in slightly different positions (and a few errant holes have been drilled but we’ve all been there).

The wiring for the control panel/thermostat is running through the cupboard under the stairs which required a clear out of all the junk in there, but also offered an opportunity to re-evaluate the storage space. Part of it has been a pantry since early 2020 as we have limited cupboard space in the kitchen but I have planned to expand it for some time. I would like some more shelving and space for a wine rack, and while leaving off things in the St Luke’s at Western Approach, I came across a stepped storage unit which looked really solid. The wicker baskets it came with were quite outdated, but the unit itself was great. All of the slats cut for the baskets will also work perfectly for modular shelving. And I got to play a little Tetris.

The icing on the cake?

Barclays, our mortgage provider, are offering a Greener Home Reward for taking on low carbon and microgeneration projects. Installing a heat pump could be worth a bonus £2000 if everything is approved. Pretty nifty and a good chunk of the installation cost.

I’ll be back next time with pictures of the finished installation and a report on how most of the first week has been. I’m interested to see if it really is as loud as some of the mud slinging articles are claiming, and if there are any early issues that crop up. Octopus Energy also claim to have excellent aftercare so we’ll be able to put that to the test. So far the installation team have exceeeded my expectations.

I better get back to sanding, filling, and painting. It has become my life…

Leave a comment